Contact person:

Shi Guoxi (General Manager) Tel: 13884663303

Wang Hongzhan (sales manager): 18865577323

Telephone\/Fax: 0535—6371732

Email:sdytruixing@163.com

Address: No. 10, Xiamen Street, Development Zone, Yantai City, Shandong Province

product description:

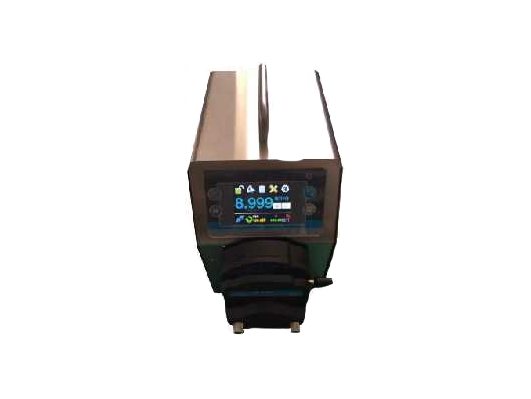

The peristaltic pump dosing machine is a new type of intelligent liquid medicine adding equipment developed by our company mainly for high-end users. The equipment consists of a regulating host and a peristaltic pump. The regulating host uses communication cables to regulate one or more peristaltic pumps. , complete the automatic quantitative addition and adjustment of one or more channels of chemical liquid. Mainly used in various mine chemical mineral processing and flotation reagents (such as xanthate, amine xanthate, sodium sulfide, No. 2 oil, copper sulfate, oleic acid and other emulsifiers , collectors, regulators, etc.), it is also suitable for the quantitative automatic addition of liquid sodium chloride and other reagents in chelation work. It is very suitable for computer networking to control the addition of reagents in industrial automation production. The model dosing machine can replace the traditional model of computer dosing machine.

System settings:

This series of automatic dosing machines consists of a vertical network anti-fouling cabinet and a stainless steel remote control cabinet. A peristaltic pump (with a small touch display) and an AC junction box (rated voltage: input AC220V) are installed in the anti-fouling cabinet. Communication terminal junction box, etc.; the remote control operation box is equipped with Siemens PLC, circuit breaker, 24V switching power supply, touch screen, etc. Specific operations can be completed on the peristaltic pump touch screen or the remote control box touch screen. In terms of application It can add chemicals continuously, evenly and accurately. It is also simple and easy to use in operation. The Chinese operation panel has sound function settings such as dosage calibration, statistics, accumulation, data analysis, and reports.

Performance characteristics:

1. Main process performance:

(1) A dosing machine is equipped with 8, 16, 24, and 32 liquid adding points (8-32 peristaltic pumps) as standard. Each liquid adding point can be conveniently started, stopped or adjusted independently, and the flow value can be adjusted independently. Accumulate the added liquid volume respectively.

Special orders will not be limited by points.

(2) The liquid volume range of each liquid filling point is 0-13000ml\/min

(3) Add the minimum liquid volume to 0.01ml\/min.

(4) The liquid filling deviation is less than 0.5 percentage (when the liquid filling volume is 100m1\/min).

(5) The host power supply is AC220V; the energy consumption of the PLC and touch screen (embedded in the computer) is <60w, and="" the="" power="" of="" a="" single="" pump="" is="">

2. Main features

(1) The entrance of the RX-BJ series dosing machine is placed at the top of the dosing tank into the medicine box. It uses a self-priming method for dosing, so it will not be affected by the pressure of the medicine box and the viscosity of the medicine. The dosing is precise. The concentration can reach 1mL. This can accurately adjust the dosage of the agent, obtain a better agent addition mechanism, reduce drug consumption to the greatest extent, and obtain better economic performance indicators.

(2) In the continuous production process, the amount of medicine that needs to be added in 1 minute can be divided into equal parts and evenly added in 1 minute according to the specific dosage required on site, so that the medicine and the slurry can fully react. The chemical method can better improve the hydrophobicity of minerals, increase the recycling rate, reduce the competitive adhesion on the surface of suppressed mineral particle bubbles, increase the floating probability of floating minerals, and also improve the quality of the concentrate.

(3) The dosing machine transports liquid by squeezing the hose with rotating rollers. The transported liquid only circulates in the hose and does not come into contact with the spare parts of the dosing machine, preventing direct contact between the liquid and the dosing machine. .The unique dosing design makes the dosing machine more suitable for adding corrosive liquids with strong acid and alkali.

(4) Choose imported hoses that are wear-resistant and corrosion-resistant. They have the characteristics of long service life and easy replacement. You only need to follow the operating instructions of the hose. Based on the specific feedback information on site, the service life of the hose For 6-8 months.

(5) Dosing calibration is simple and easy. There is no need to calibrate repeatedly for long-term applications. You only need to calibrate once after installing the equipment. After calibrating once according to the operating instructions of the dosing machine, the dosing machine will automatically save the calibration results and use it again. When changing the dosage, there is no need to recalibrate, and the accuracy can be 1mL.

Previous: Diaphragm pump dosing machine