Contact person:

Shi Guoxi (General Manager) Tel: 13884663303

Wang Hongzhan (sales manager): 18865577323

Telephone\/Fax: 0535—6371732

Email:sdytruixing@163.com

Address: No. 10, Xiamen Street, Development Zone, Yantai City, Shandong Province

Introduction:

According to specific research, the energy consumption of the ball mill accounts for more than 50% of the energy consumption of the mineral processing plant. The power of the ball mill motor is positively related to the filling rate of the ball mill. But if the filling rate is too large, because there are too many balls, the inner layer of balls will be filled when the ball mill is running. It is easy to cause interference, destroying the normal circulation of the balls, which will reduce the grinding efficiency. If the filling rate is too small, even though the motor power is small, the grinding efficiency will also be reduced because of insufficient grinding media. It can be seen that the power of the ball mill motor The size depends on the filling rate of the ball mill, and the filling rate directly affects the grinding efficiency of the ball mill. In theory, it is ideal to automatically add one steel ball within the time that the ball mill consumes one steel ball. The way to achieve this ideal state is to use an automatic ball adding machine.

The "RXJQ Series Ball Mill Automatic Ball Adding Machine" produced by our company can improve the precision of the ball adding amount, and can accurately add the ball amount per minute or hour, reducing the labor of the ball mill operators and making the ball mill achieve better results. The operation effect of the ball mill is improved, and the service life of the ball mill is extended. It also reduces the ball consumption, steel consumption and energy consumption of the mill. The automatic ball adding machine is safe and reliable in operation, easy to maintain, simple to operate, reasonable in structure, good in stability, no ball jamming, and no The fluffy ball has the characteristics of strong adaptability to various types of steel balls with different hole diameters. It has the functions of regularly adding balls evenly, adding the total amount of balls, and automatically stopping when there is no ball alarm, which is beneficial to maintaining a reasonable ball diameter ratio and steel ball in the ball mill. ball filling rate, thereby improving grinding efficiency.

The structure of automatic ball adding machine:

The equipment is composed of driving equipment, actuator, ball bin and control part. The actuator is composed of reducer chain sprocket and ball claw on the chain. The control equipment is composed of PLC and operation control box. The settings of the ball adding machine are The number of added balls can be set arbitrarily within the range and the total amount of added balls can be displayed. At the same time, it can complete no-ball and fault alarm shutdown. The ball adding machine can be freely converted between manual and automatic operation.

(1) Transmission mechanism.

The transmission mechanism is directly driven by a slow-speed 3-phase asynchronous motor to provide power for the system. The speed ratio can be selected from 1-7r\/min, which can be adjusted according to the specific application.

(2) Monitoring system.

1. Inspection of the number of steel balls.

2. Check the working current of the ball adding machine.

(3) Control system hardware and software.

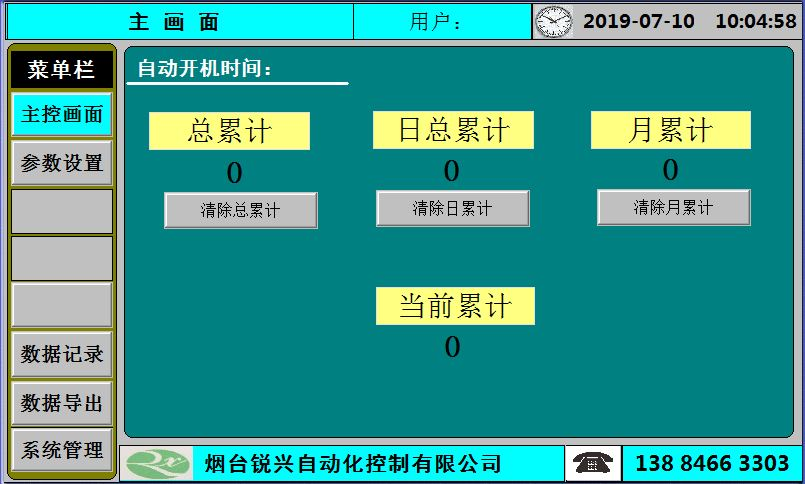

The hardware part of the control system is designed with a programmable control panel and a touch screen. The main functions are: it can automatically add steel balls according to the set time; it can be switched to manual mode to continuously add steel balls to the ball mill; and it can be added on the touch display The screen displays the current number of added balls, class total, daily total and monthly total, and has the function of historical report inquiry; it has over-voltage protection, system interlocking, fault self-examination and explanation, network communication and other functions.

Basic elements:

1. Set the amount of balls added as needed;

2. Conversion between manual ball adding and automatic ball adding;

3. No ball vibration, fault shutdown, overvoltage protection;

4. Display the amount of balls added and the total amount of balls added;

5. Inspection of the amount of balls added;

7. Operating time display;

8. Touch screen operation, simple and convenient;

9. Other functions can be added according to on-site requirements.

Automatic ball adding machine selection:

Ball adding machine model | Ball adding machine specifications | self-respect | Capacity | Remark |

RXJQ-5 | 2.6m1.2m1.8m | 1.5t | 5t | Each 80-180 ball adding machine is equipped with a motor (2.2kw) and a reducer (model xwd4-87); the 60-20 and ball adding machines are equipped with a motor (1.5kw) and a reducer (model xwd4 -43), equipped with one vibration motor (0.75kw) |

RXJQ-4 | 2.4m1.1m1.6m | 1.3t | 4t | |

RXJQ-3 | 2.4m1.0m1.5m | 1.2t | 3t | |

RXJQ-2 | 2.2m0.9m1.5m | 1.0t | 2t | |

DualRXJQ-5 | 2.6m1.8m1.8m | 2.0t | (5 plus 5)t | The double A380-180 ball adding machine is equipped with 2 motors (2.2kw) and 2 reducers (model xwd4-87); the double A360-20 ball adding machine is equipped with 2 motors (1.5kw) and 2 reducers (model xwd4 -43), 2 vibration motors (0.75kw) |

DualRXJQ-4 | 2.4m1.6m1.6m | 1.8t | (4 plus 4)t | |

DualRXJQ-3 | 2.4m1.4m1.6m | 1.6t | (3 plus 3)t | |

DualRXJQ-2 | 2.2m1.4m1.5m | 1.4t | (2 plus 2)t |

Performance parameters:

1. Installation dimensions: The total dimensions are: 1000 mm (width) 2400 mm (length) 1600 mm (height)

The height is adjusted according to the tonnage, and the default setting is 1000 mm.

2. Steel plate thickness: 10 mm

Note: The thickness of the steel plate can be customized according to the actual net weight of the steel ball.

3. Net weight:≈1.1T

4. Ball specification: Φ20mm-Φ150mm

Note: Ball-adding specifications can be customized according to on-site requirements.

5. Ball bin capacity: ≈3.5T

Note: It can be adjusted according to the specific conditions on site.

6. Motor power: 1.1KW slow speed motor (7r\/min)

7. Adding ball capacity: 28 balls\/minute

Note: It can be changed according to actual needs on site.

8.Control panel

Choose the German Siemens SMART series.

The main screen of ball adding machine operation

Ball adding machine parameter setting screen

Previous: Solenoid valve dosing machine